Straightening service is a vital technique for correcting deformities and ensuring the structural integrity of metal components. For years, HDH Instruments has been leading in providing top-notch straightening services. With decades of specialized experience, our craftsmen are committed to delivering exceptional results across various industries, ensuring the highest standards of quality and accuracy.

Straightening Capabilities

- Up to 45 Ft Length

- Diameters up to 16.50” OD

What is A Straightening Press?

A straightening press is a machine with a hydraulic ram used to straighten or correct deformities in metal or other materials by applying controlled pressure or force. It is commonly used in metalworking and manufacturing industries to correct bends, twists, or warping in components or parts.

Techniques Used in Straightening Services

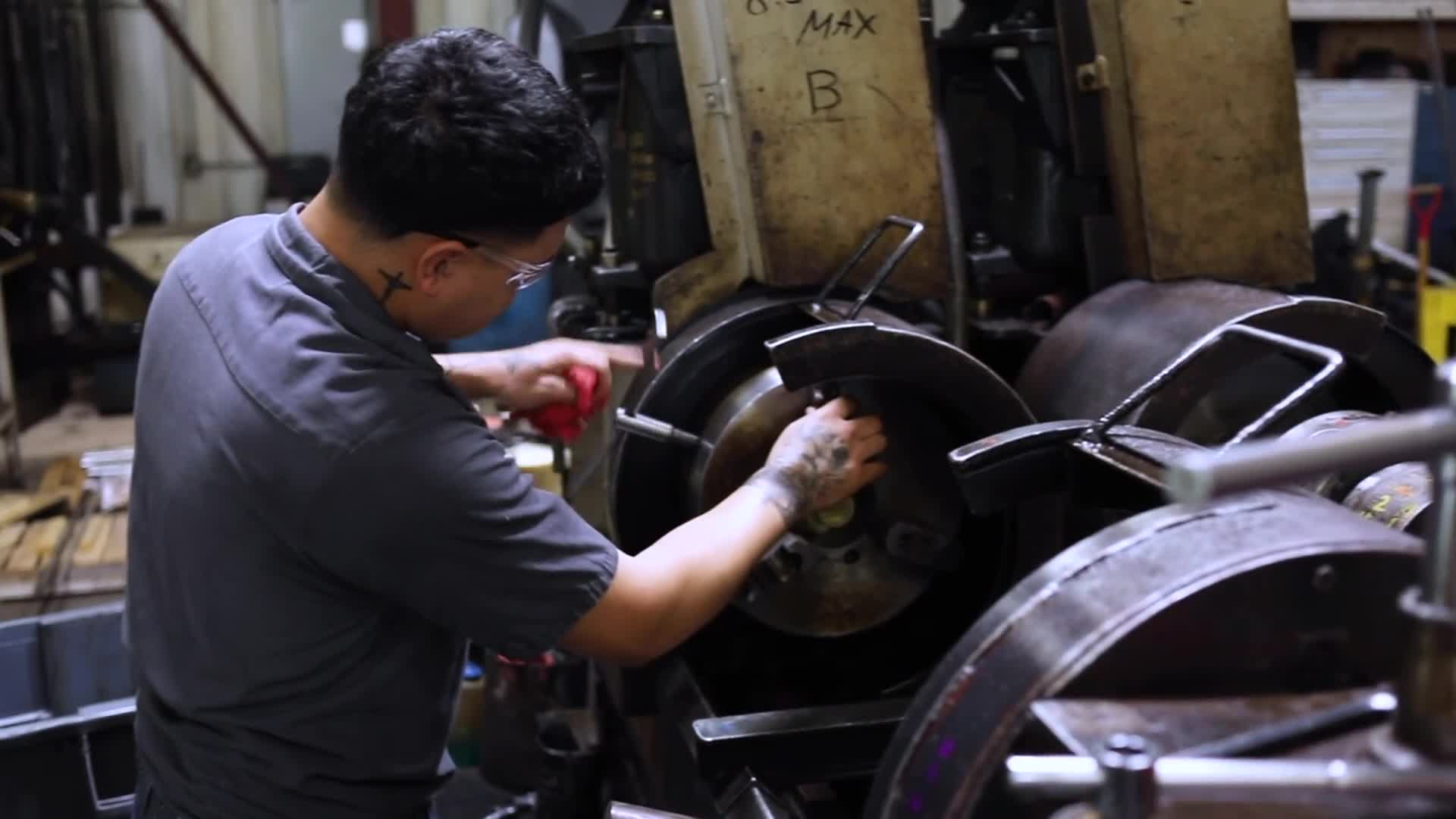

Straightening services employ various techniques to modify the structure of materials, particularly metals, to attain desired shapes and dimensions. The effectiveness of these techniques depends on the composition of the material, the degree of deformation, and the required level of precision. Key techniques include:

- Press Straightening: Press straightening involves applying controlled force using hydraulic or mechanical presses to reshape the metal component.

- Heat Straightening: Heat straightening utilizes localized heating to soften the metal, making it more malleable and allowing it to be reshaped.

- Cold Straightening: Cold straightening involves applying force at room temperature without the use of heat, often using leverage or mechanical devices.

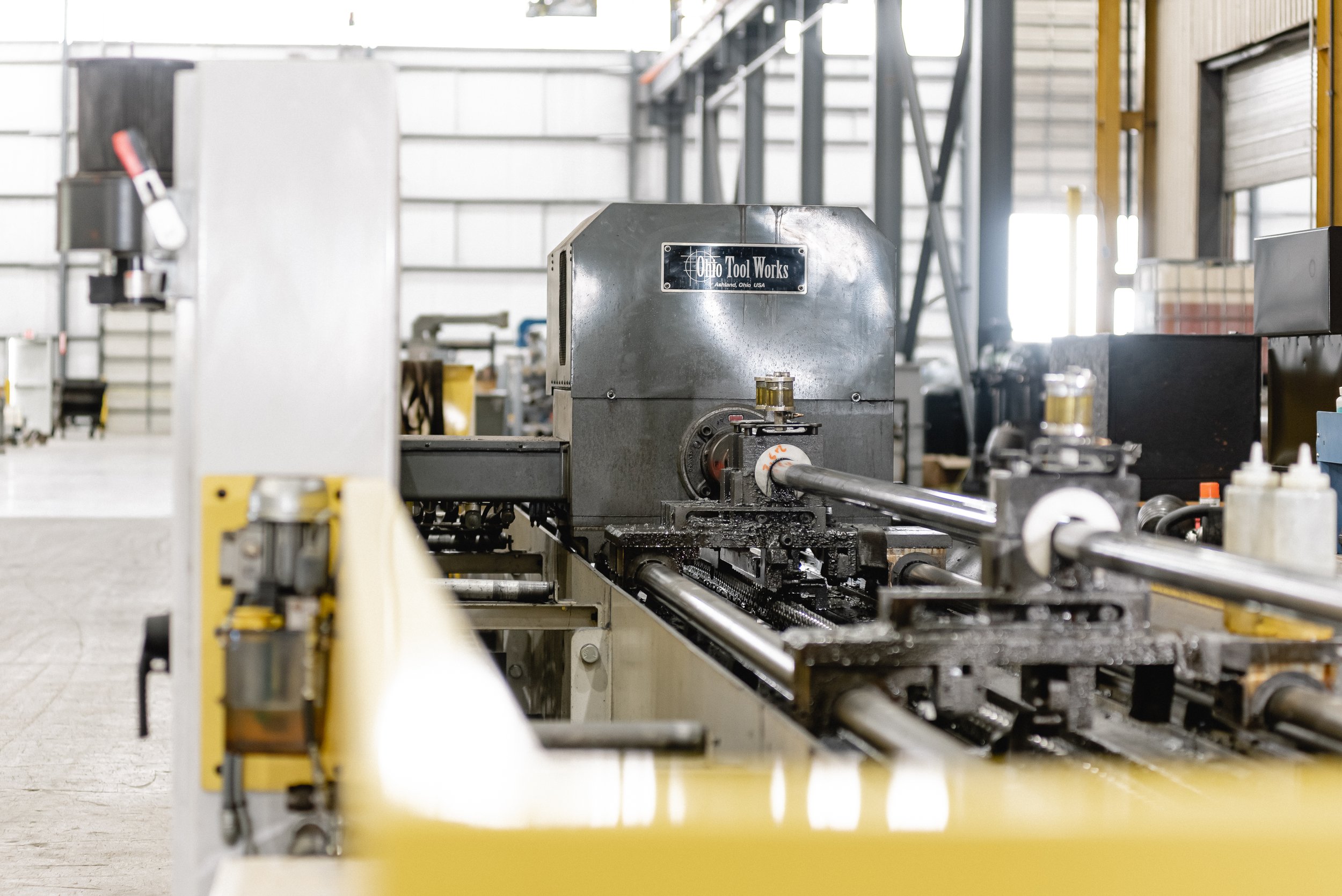

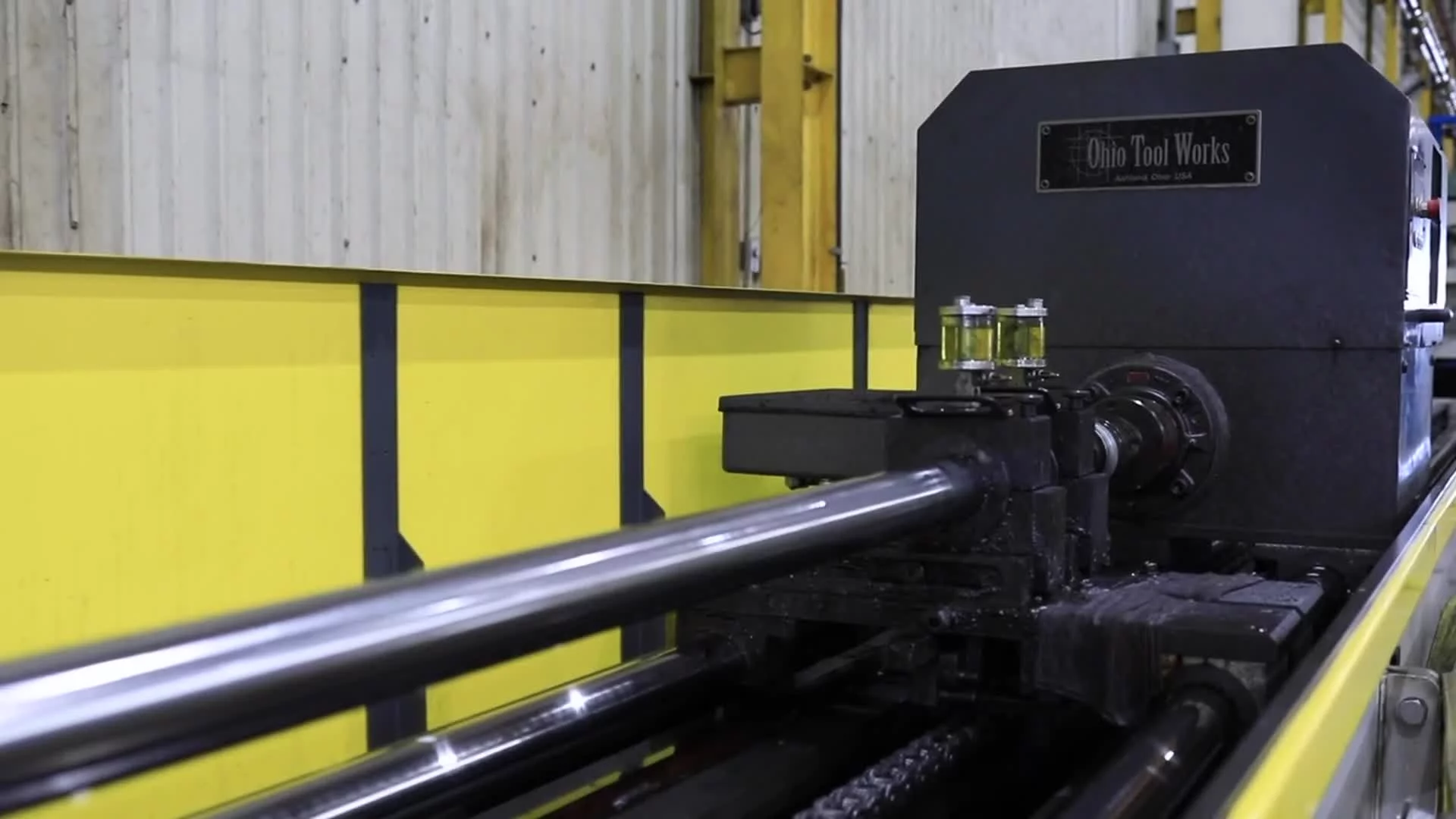

Straightening Press Power of HDH Instruments

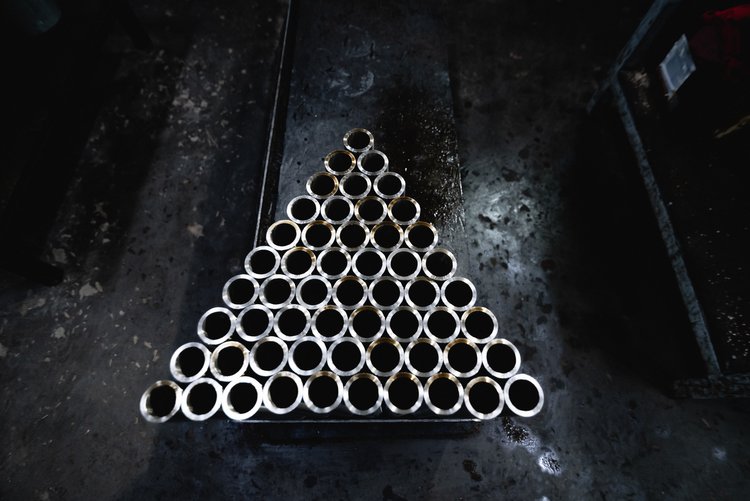

Our facility features straightening presses with capacities ranging from 50 tons to 1,000 tons, allowing us to handle various materials such as large raw bars or thin-wall finished tubes. Our equipment is designed to deliver extraordinary results.

Key Specifications

- Length Handling: Up to 45 feet, accommodating substantial components.

- Diameter Capacity: Handles up to 16.50 inches OD, ensuring versatility for numerous applications.

Why Choose Straightening Services of HDH Instruments?

At HDH Instruments, our proficiency in honing, drilling, and beyond extends to our comprehensive straightening services.

Our unique position in the market is not just a product of our advanced machinery, but also of our extensive expertise and commitment to quality. Our team comprises 175 dedicated professionals equipped with specialized pieces of equipment that include:

- 33 Deep Hole Drilling/Boring Machines

- 8 Gun Drilling Machines

- 25 Honing Machines (Vertical & Horizontal)

- 26 Hollow Spindle Lathes

- 7 CNC Lathes

- 7 Straightening Presses

This powerful setup allows us to execute various tasks with high precision, ensuring that every component meets the strict quality standards of numerous industries.

Our straightening services play a critical role in ensuring that components meet your exact specifications. Our powerful technology and expertise allows us to correct irregularities with exceptional accuracy that guarantees superior performance and reliability.

Press Start and Start Pressing with HDH Instruments!

At HDH Instruments, we are committed to delivering drilling services that not only meet but exceed expectations. Our extensive experience, combined with a nonstop pursuit of perfection, positions us as the preferred partner for businesses needing precise gun drilling services.

Work with us, and together, we will achieve outstanding results. HDH Instruments is here to elevate your project’s precision with our expert gun drilling services. Get in touch with us and discuss your specific needs and how we can customize our capabilities to support your objectives.