Since 1978, HDH Instruments has provided dependable deep hole drilling and precision machining services for demanding industries. Our facility handles large-scale, high-volume projects with accuracy and consistency, supporting energy, aerospace, defense, and industrial markets. From initial drilling to final machining, we offer eight service categories designed to deliver precision in both process and performance.

Deep Hole Drilling Services

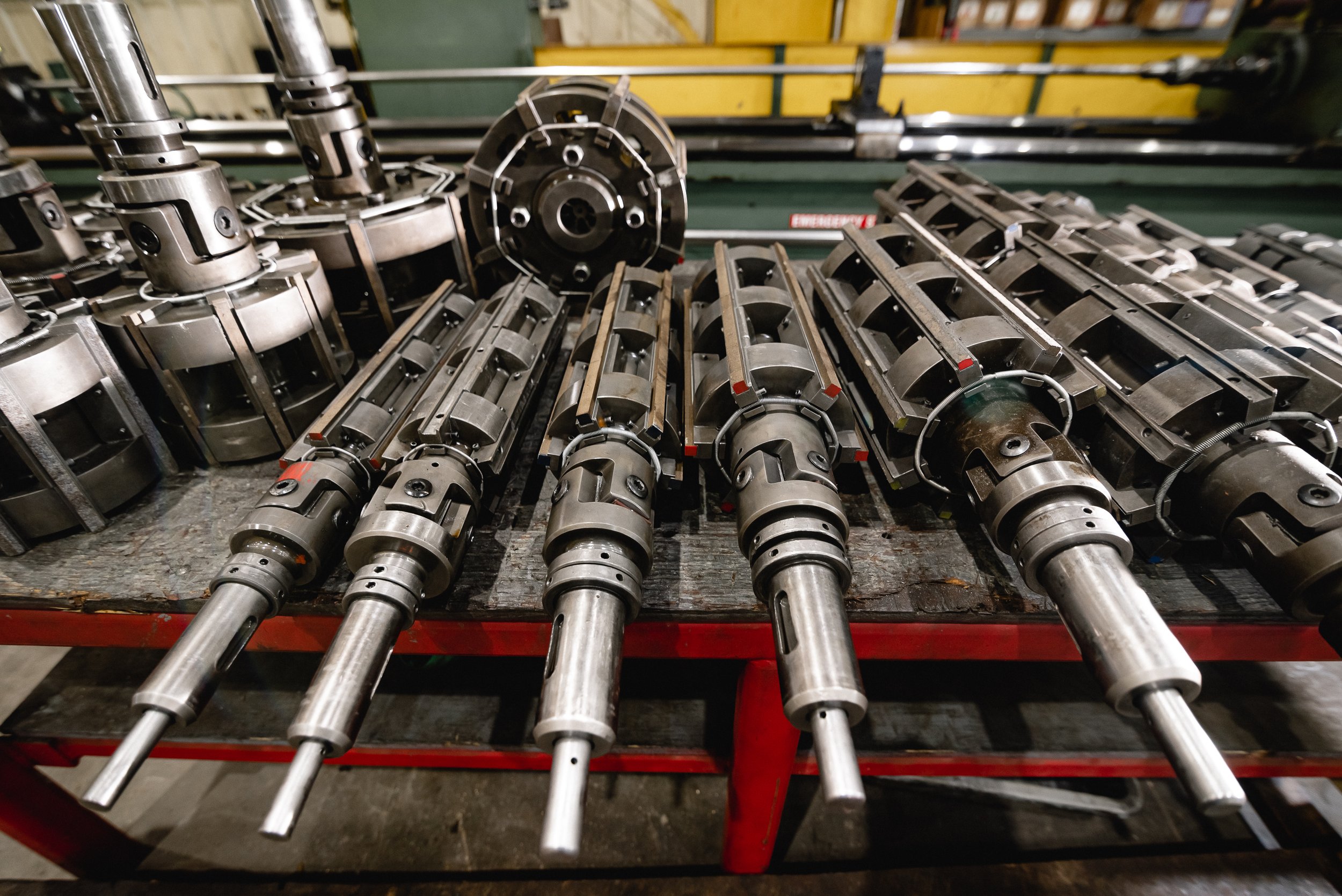

Deep hole drilling is a core capability at HDH Instruments, where over 30 machines are dedicated to processing long-length tubulars and heavy-wall components for demanding industries. This method allows us to achieve exceptional depth-to-diameter ratios—well beyond those of standard drilling.

Our advanced equipment supports:

- Diameters from 0.984” to 8.00” (up to 14.00” with trepanning)

- Lengths up to 420”

- Machining of carbon steel, stainless steel, nickel-based alloys, and other high-strength materials

Our services are frequently used in the production of bottom hole assembly components, shafts, housings, and other various drilling & completion components. High accuracy, alignment, and clean internal finishes are maintained throughout the bore — all essential for precision-driven applications.

In addition to standard deep hole drilling, HDH Instruments offers trepanning services for large-diameter components (up to 14.00” ID), making this process ideal for applications requiring hollowing of high-end stainless and nickel alloys that are typically produced as solid bar stock. An additional benefit of this process is the retention of a solid core that can be further used in the testing or manufacturing process.

Tube Boring Services

HDH Instruments handles high-precision tube boring for energy, drilling, defense, and mechanical system components. This process is best suited for long tubulars which require more refined tolerances and surface finishes than what can be provided as is from a steel mill. Tolerances as tight as ±.010” and finishes as good as 63 Ra can be achieved, depending on certain factors.

Capabilities include:

- Inside diameters from 1.80” to 8.50”

- Lengths up to 45 feet

- Capable of processing all grades from carbon steel to high end nickel alloys

This service supports manufacturers working with pressure-rated tubing, hydraulic cylinders, various oil & gas downhole components, and many other tools. Bores are kept straight and smooth for ideal flow and strength characteristics.

Gun Drilling Services

Gun drilling is a critical process for creating precise, deep holes with small diameters and smooth internal finishes. HDH Instruments provides this service to industries requiring high accuracy, including aerospace drilling applications where component integrity and dimensional control are important.

Gun drilling capabilities:

- Diameters from 0.055” to 1.50”

- Lengths up to 150” (diameter-dependent)

- High-pressure cooling and chip evacuation for deep-hole stability

Our capabilities are perfect for aerospace gun drilling services, supporting the production of mission-critical parts used in flight systems, propulsion assemblies, and landing gear. The process offers tight concentricity and minimal deflection throughout long bores, not achievable through other machining methods.

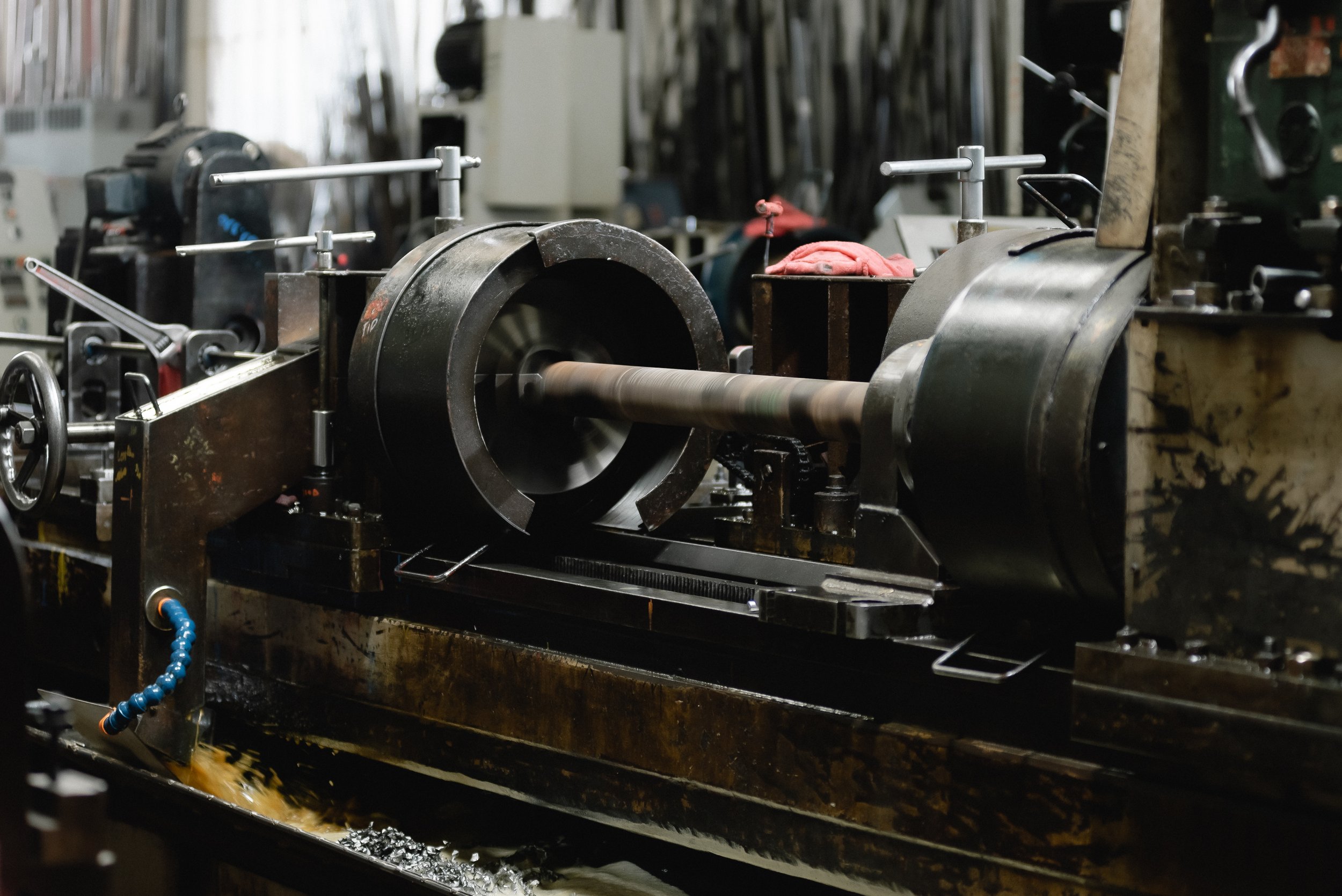

CNC Turning Services

Precision CNC turning plays a key role in shaping outer surfaces and finishing deep-drilled parts. HDH Instruments uses both conventional and CNC lathes to process housings, stator tubes, and custom parts to exact print dimensions.

Turning capabilities:

- Outside diameters up to 24.00”

- Lengths up to 492”

- Tolerances as tight as 0.005”

This process supports both short-run parts and high volume repeat production orders. HDH turning services are often used for parts destined for downhole drilling assemblies, aerospace assemblies, and energy equipment.

Honing Services

Honing enhances bore geometry and surface finish after deep hole drilling or boring. HDH Instruments maintains both vertical and horizontal honing equipment to accommodate both long and short parts, large diameters, and non-stand part configurations.

Our honing operations offer:

- Diameters from 0.500” to 24.00”

- Lengths up to 600”

- Surface finishes down to 8 Ra or better

This step is often required for hydraulic cylinders, fluid channels, and precision tube assemblies. Honed surfaces support better flow, reduced friction, and tighter control of internal tolerances.

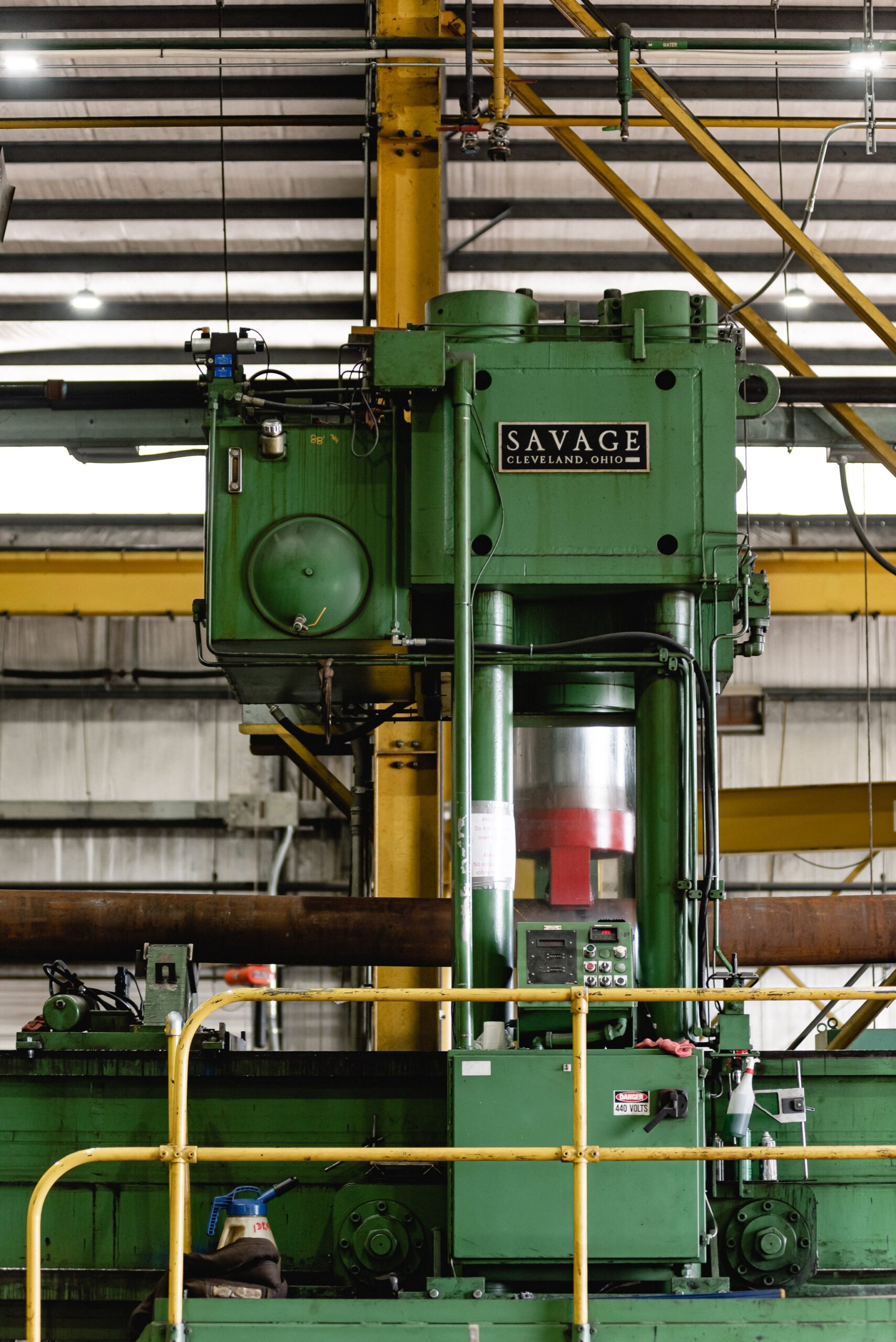

Straightening Services

Long parts can bend or warp during machining or heat treatment. HDH offers precision straightening using a series of hydraulic presses to bring components back within specification. With 8 presses of varying strengths and sizes, HDH has both the capacity and capability to accommodate parts of all sizes and thicknesses.

Straightening capability:

- Diameters up to 16.50”

- Lengths up to 45 feet

- Presses from 50 to 1,000 tons

This process is essential for long shafts, bottom hole tools, and tubular structures where alignment or high speed rotation is critical to performance and fit.

Downhole Machining & Bottom Hole Assembly Tool Conversion

HDH Instruments delivers expert downhole machining and bottom hole assembly (BHA) tool conversion services tailored to the oil & gas industry. Our precision machining ensures accurate alignment of connections and welding of tool joints on heavy-duty tubulars and drilling components.

Our downhole machining capabilities include:

- Size conversion on both full length and pony collars (both OD & ID)

- Conversion of slick collars to flex collars

- Pitting removal through bore enlargement and roller burnishing

- Step boring and profiling converting standard subs into UBHO subs and other like components

- Stub weld drilling and boring to repurpose existing non-magnetic collars rather than purchasing brand new tools

- Precision deep hole boring to maintain tight tolerances in critical bores

In addition, our bottom hole assembly tool conversion services cover modification and preparation of components such as drill subs, pony collars, and crossover tools to client-specific threading and fitment standards. Our manufacturing capacity supports fast turnarounds and short-notice requirements, helping keep field operations running smoothly.

Industries Served & Applications

- Oil & Gas – Machine drill collars, BHA components, crossover subs, and stabilizers used in directional drilling and wellbore operations, as well as various components of typical completion tool systems

- Aerospace – Produce landing gear components, fuel delivery tubes, engine shafts, and actuator housings requiring high-accuracy internal bores.

- Energy & Power Generation – Support turbine and pressure system manufacturing with boring and honing of steam shafts, heat exchanger tubes, and pressure vessel parts.

- Defense & Military – Supply gun barrels, large munitions shells, structural frames, and driveline parts for mobile and tactical systems.

- Mining – Manufacture drill rods, cutter heads, crushing equipment components, and wear-resistant parts used in mineral extraction and processing.

- Heavy Equipment & Industrial – Machine hydraulic pistons, drive train shafts, and rotating components for mining, construction, and factory machinery.

Why Choose Our Services?

At HDH Instruments, we stand out for our dedication to precision, quality, and reliability. Here are the key reasons why clients choose us for their deep hole drilling and machining needs:

- Industry Expertise – With decades of experience, we understand the unique demands of industries like oil and gas, aerospace, energy, and defense.

- Precision and Accuracy – We guarantee tight tolerances and high-quality finishes, making sure that every part meets the most strict specifications.

- Custom Solutions – Whether it’s deep hole boring, CNC turning, or downhole machining, we customize our services to match the specific needs of each project.

- Timely Delivery – We pride ourselves on quick turnaround times without sacrificing quality, ensuring that your projects stay on schedule.

- Competitive Pricing – Our efficient processes and advanced technology allow us to offer cost-effective solutions, making precision machining affordable for all.

Choosing HDH Instruments means choosing a partner who delivers dependable results with unmatched precision.

Start Your Big Projects with HDH Instruments

Operating from a 225,000-square-foot facility equipped with more than 100 machines, HDH Instruments processes thousands of feet of material annually. Our experience in long-length drilling, combined with the ability to finish, inspect, and repair, provides a complete solution for industries where reliability is a priority.

For service inquiries, capacity questions, or scheduling, please do not hesitate to contact us. We look forward to supporting your next drilling or machining requirement.